CUTLERY WRAPPING MACHINEFULLY AUTOMATED SYSTEM WRAPS CUTLERY INTO NAPKIN PAPER – HYGIENIC AND PLASTIC-FREE

The cutlery wrapping machine with Fillomat (automatic wrap distributor) helps you to save time and optimize labour costs. Your large-scale catering facilities management will profit thanks to the easy hygienic operation, as well as the increase in frequency and the associated convenience.

Due to its mobility and compact design, the cutlery wrapping machine allows a flexible, space-saving integration into your individual kitchen planning. The solid, stainless steel covering guarantees that the machine will last for many years.

IT’S THIS EASY TO USE THE CUTLERY WRAPPING MACHINE TD 800

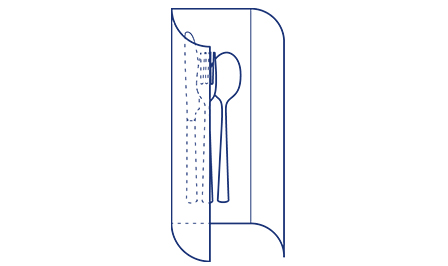

Our cutlery wrapping machine hygienically wraps up to 800 sets of cutlery per hour into an optical appealing napkin paper wrap. The desired combination of clean, washed cutlery (max. 4 – 5 pieces) are placed into the feed chute of the cutlery wrapping machine. From here, the full automatic wrapping process of the cutlery set into a napkin begins. The wrap is sealed by means of perforation which allows an easy opening of the wrap without damaging the napkin.

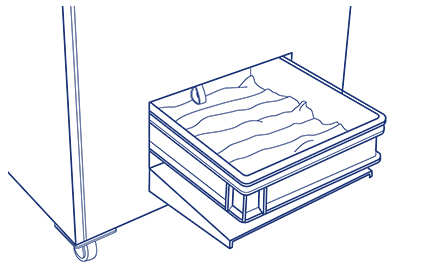

The integrated “Fillomat” distributes the wrapped cutlery sets directly into a cutlery bin. The amount of cutlery sets per box can be individually programmed as desired (between 44 – 66 wraps/box). Once the adjusted amount of cutlery sets have been achieved, the machine will stop while the display panel notifies the operator to replace the cutlery bin. The bin can be easily exchanged.

ORIGINAL DÖRR NAPKIN PAPER

for THE CUTLERY WRAPPING MACHINE TD 800

In the future, hygiene will play a huge role for your guests. Wrapping cutlery in napkins prevents the spread of bacteria and viruses.

YOUR ADVANTAGES AT A GLANCE

Cutlery sets are automatically wrapped into a napkin

Compact and hygienic packaging

Automatic sorting of wrapped cutlery sets into cutlery bins

Flexible, time independent preparation

Environmental and ecologic

Without additional plastic waste

Easy handling thanks to the clearly arranged operating panel

Optimized personnel deployment due to time savings

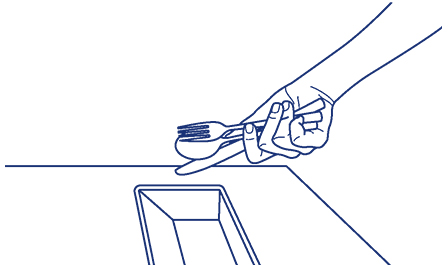

Placement on a tray with just one hand grasp

Avoids shifting of singular cutlery pieces during transport

Suitable, sturdy and extremely absorbent quality napkin paper

Individually printable upon request

Technical data

Cutlery wrapping machine TD 800

| Dimensions (W x H x D) | 190 x 127 x 80 cm |

| Weight | 335 kg |

| Connected load | 150 W |

| Power supply | 100 / 240 V - 50 / 60 Hz |

| Extras | integrated counter; integrated Fillomat distributor |

| Housing | stainless steel enclosure |

| Maximum cutlery length | 220 mm |

To ensure safe and easy handling, we offer suitable accessories for our cutlery wrapping machines. Our cutlery containers are available in three different colors (blue, red, gray) to help you allocate and/or distribute wrapped cutlery sets to the right meals (breakfast, lunch and dinner). We also offer a trolley on which you can stack the containers, making it easier to transport them to the ward, serving counter or food distribution conveyor. We are happy to discuss your individual options.

| Art. No. | Description |

| 0003415 | Cutlery container blue |

| 0003415 | Cutlery container red |

| 0003415 | Cutlery container gray |

| 1004591 | Trolley for cutlery containers |

Adjusting the number of sets to be wrapped

Inserting the paper roll

Homing

Other settings

Error messages

Turning off the machine

Emergency stop

Cutlery jammed under knurled rollers

Replacing the blades

Daily cleaning

Weekly cleaning

Bi-weekly cleaning

Our TD 800 cutlery wrapping machine wraps sets of cutlery in napkin paper, in a manner that is both hygienic and appealing to the eye. The desired combination of cleaned cutlery (max. 4-5 pieces) is inserted into the filling chute, after which the machine takes over, wrapping the cutlery sets in high quality napkin paper in a fully-automated process. Once wrapped, the cutlery is automatically sorted into the cutlery container.

It only takes one person to operate the machine, which can wrap up to 800 cutlery sets per hour. Allowing for interruptions to change the containers, the paper rolls and for short breaks, the machine wraps around 650 cutlery sets per hour in practice,

compared to approx. 200-250 cutlery sets per hour when wrapped by hand.

We guarantee at least 6,000 wrappings per roll of napkin paper; however, generally each roll yields up to 6,500 wrappings.

Pieces of cutlery should be no longer than 220 mm, as otherwise they may cause disruption in the machine. However, upon request we can convert the machine to accommodate a maximum length of 223 mm.

Each napkin packaging can hold a maximum of five pieces of cutlery. Other items such as packets of salt and pepper and similar can also be added.

Up to a wrapping capacity of 4,500 cutlery sets per day we advise against sorting the cutlery in advance. The machine takes about five seconds for each wrapping, giving operators enough time to take the next pieces of cutlery out of an unsorted cutlery container. Simply position the cutlery container on top of the machine, next to the filling chute.

If you need to wrap more than 4,500 cutlery sets per day, we recommend employing two cutlery wrapping machines. In this case, it may make sense to sort the cutlery before use, as then one person can operate both machines.

The wrapped cutlery falls into a container that is situated on an integrated Fillomat distributor. The Fillomat distributor moves incrementally from side to side, ensuring the container is filled evenly with wrapped cutlery sets. Once the container is full, the machine signals that it needs changing.

The size of the napkins is comparable to that of most napkins provided in the health care sector. However, the napkins used in our cutlery wrapping machine have three layers and are thus thicker and more absorbent, and ultimately of a higher quality, than conventional napkins.

The wraps are perforated on both sides to seal them. The sealing thickness is adjustable. The wrappings are extremely stable during conventional handling.

Diners can easily open the packaging without destroying it, as the seal has only been embossed. If cutlery is still in its packaging when it is returned for cleaning, it can easily be removed by giving the packaging a sudden shake, one of the greatest benefits of this type of packaging, along with the fact that it avoids plastic waste.

The cutlery pouches are compatible with all conventional trays. However, they are longer than wrappings made by hand.

- Daily: Wipe the filling chute incl. sensor and reflectors with a damp cloth. Duration: approx. 1 min.

- Weekly: Wipe chute flap, control panel and conveyor belt with a damp cloth; then rub with a dry cloth. Clean the gear cogs and racks in the engagement assembly with a brush. Duration: approx. 10-15 min.

- biweekly: Guide slide bearings: Vacuum the Fillomat’s guide rail underneath the slide carriage, the gear racks in the engagement assembly (left and right) and the miniature guide slide bearings beneath the shaft base plate and all dusty parts (base plate, etc.). Duration: approx. 15 min.

If there is no more paper left on the roll, the display will indicate this. A new roll will then have to be inserted.

The machine reduces the steps required to prepare trays at the food distribution conveyor from five to one, which can be performed by one person at the conveyor belt, thus freeing the other worker up for other jobs.

Compared to wrapping cutlery by hand, employees are approx. three times as fast and no longer have to sort cutlery manually to boot. We are happy to provide you with an amortization plan.

Provided it is cared for and serviced properly, the machine has a service life of approx. 10-15 years, depending on use. From time to time, the blade that separates the napkin from the roll will need sharpening; a spare blade is included in delivery.

In hospitals, clinics as well as in supply centers across the world. We are happy to provide references upon request.